A Commitment to Safety: Inside MSR’s World-Class Water Research Lab

Behind every MSR water treatment and hydration product is a team of scientists dedicated to researching, developing and testing the latest in water treatment solutions. Established in 1997, our on-site microbiology lab is crucial to MSR’s water program and the safety and reliability of our products. Initially founded to ensure quality control, today the lab’s world-class efforts stretch into research of new technologies, testing and development for the U.S. military, and contracts with nonprofit organizations working in developing nations.

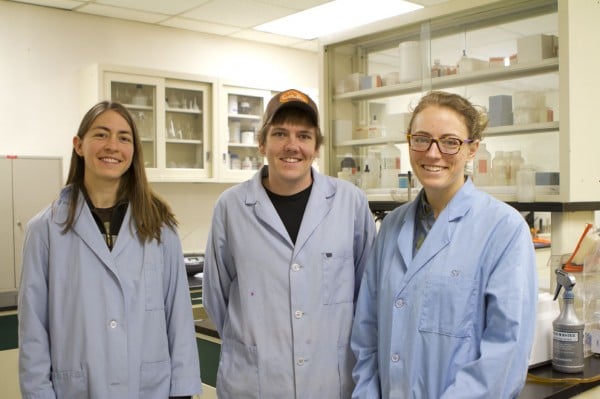

The lab is located at our Seattle headquarters, in close proximity to our production lines, and is staffed by five scientists with advanced degrees in chemical engineering, biochemistry, microbiology, environmental science and cellular and molecular biology. The world inside this small space is fascinating, with an incredible amount of scientific knowledge. Here’s a look inside.

The Lab

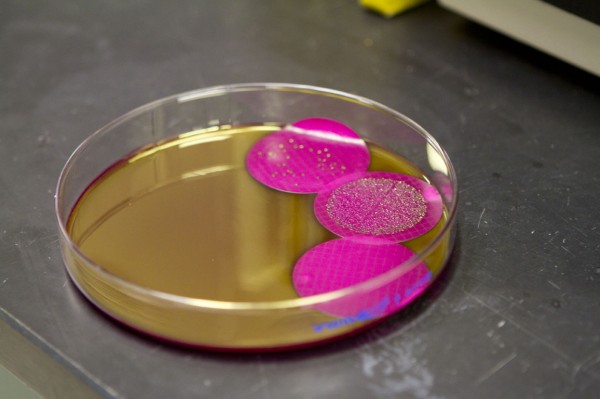

As a Biosafety Level 2 lab allowed to house live pathogens, the MSR lab grows and meticulously maintains its own bacteria and viruses as samples for research and testing. Every day, the team works with these organisms in some capacity. They may test the types of contaminants a technology removes, how long it lasts or under which conditions it’s effective. They must carefully manage these cultures to ensure they’re always working with the right strain of pathogen, crucial for meeting efficacy testing requirements.

Using a spectrophotometer to measure the absorbance of various wave lengths of light produced by contaminants in the water, the team can determine whether a technology has removed threats, or added new ones, to their samples.

With access to nearly every type of water treatment technology available to modern science, the lab team has hands-on experience with the latest in UV, filtration (membranes, fibers, plastics, cellulose, string, metals, ceramics), adsorptive media and chemical treatments. By knowing the advantages and limitations of each, MSR can develop the safest and most-sound solution to a particular real-world water treatment challenge.

In fact, the lab was crucial in our development of ceramic extrusion technology, recognized in 1998 as one of the top innovations in ceramics in the last century. And in 2003, MSR’s acclaimed MIOX® purifier was adapted for the outdoor market after a 5-year development process with the U.S. Defense Department to allow soldiers to purify any water. That year, Popular Science recognized it with their Grand Prize for Innovation.

Still, the lab’s number one priority is ensuring that we can stand confidently behind our products and claims. Therefore, every single production run each week is quality assured.

Efficacy Standards

At MSR, we consider water filters and purifiers to be what they are: health care devices protecting you from illness. So we design products to meet the efficacy standards set by the scientific community for removal of threats—like you, we use and trust our products for our own adventures. This agreed upon test procedure is known as NSF Protocol P231, an updated, more stringent protocol to the EPA’s older guidelines. It’s a 10-day, multi-criteria test. Every MSR treatment device meets its efficacy requirements, even when tested with “worst-case” water, containing high levels of turbidity and natural organic matter, and at harsh temperatures and pH—and even when the cartridge is at the end of its life. The ultimate goal is to be confident that our products can endure conditions that exceed those under which they’d ever be used in the real world—and therefore prove their in-field reliability.

Afterward, we send our products to certified third-party labs to confirm that our test results are unbiased.

Global Partnerships

The lab’s close proximity to MSR’s production factories means the team has an unparalleled understanding of every step in the process of turning a scientific idea into a manufactured, commercial product. Because of this and the lab’s depth of knowledge, the U.S. military and international nonprofit organizations like the Gates Foundation and PATH have contracted with the lab for testing and development of new solutions to water and sanitation treatment challenges for soldiers and citizens of developing nations around the world.

The knowledge concentrated in the lab has, in fact, made it a sought-after resource for everyone from DIY-garage inventors to university professors conducting water treatment research.

What It All Means to You

Besides the fact that we think science is really cool, owning our own microbiology lab gives us an incredibly high level of technological research and development. We invest heavily in our water lab so that we can guarantee the safety and reliability of our products. After all, Larry Penberthy founded MSR on the principle of improving the safety of backcountry travelers and the water lab is a big way we stay committed to that goal with products we’re proud to put our name on and see users rely on in the field.

As Zac Gleason, lab supervisor, says: “It’s great to work for a company that is committed to the safety and enjoyment of their customers. MSR has become a brand to trust for delivering product that goes above and beyond. I don’t think any of us in the lab would be able to work for a company that compromised on quality and testing so that it could sell a few more filters.”